RFID Tunnels

The RFID Tunnel Conveyor Solution utilizes RFID technology to automate the inventory counting process, providing high-speed tag reading and achieving accuracy rates of up to 99.9%.

RFID Tunnel Conveyor Solution

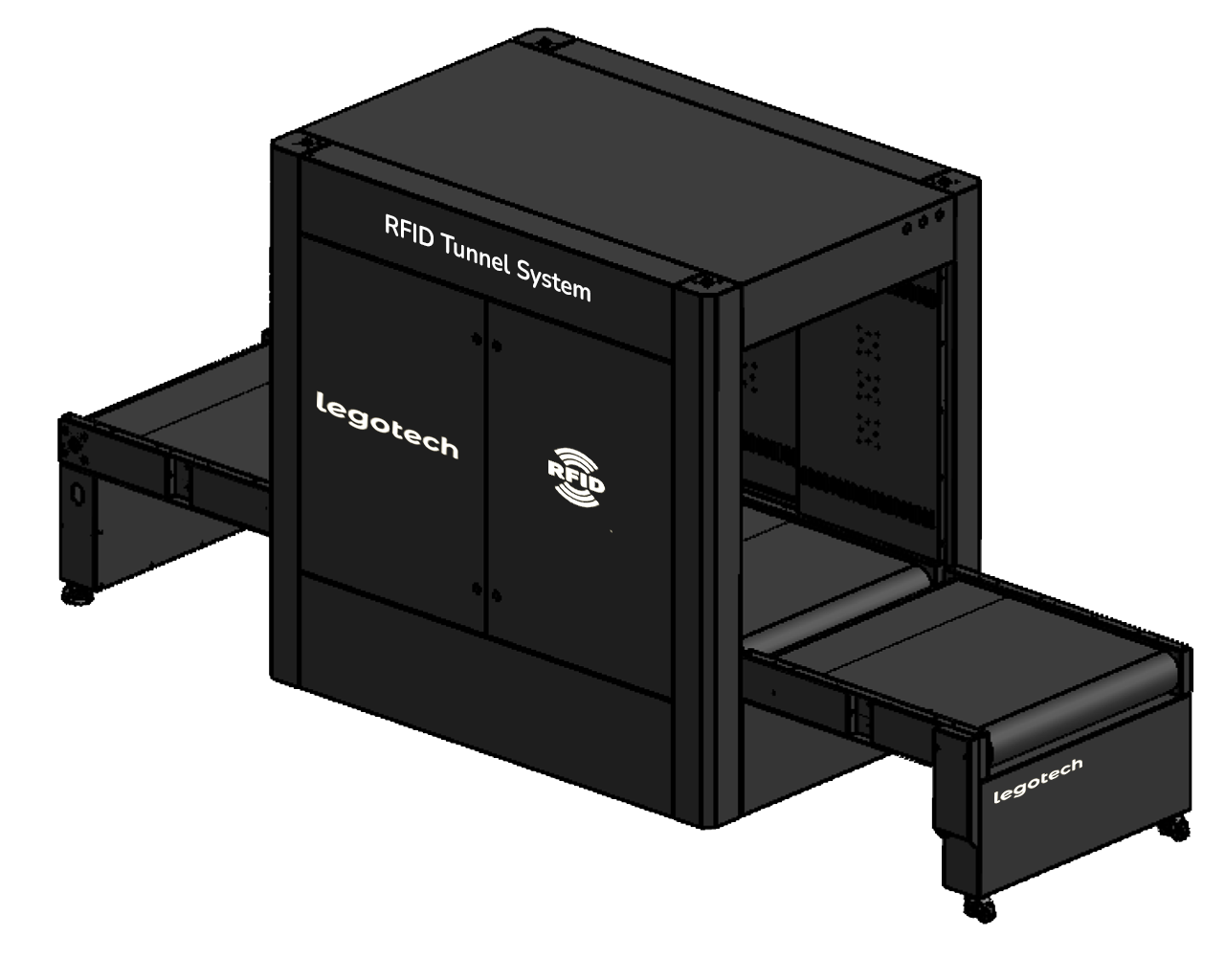

The RFID Tunnel (or RFID Conveyor) is a fixed RFID system integrated into conveyor lines in warehouses, manufacturing plants, and retail distribution centers. The system consists of RFID readers and antennas enclosed within a shielded tunnel structure, enabling the automated counting and identification of items passing through with high precision and reliability.

Order Management (PO)

Error Detection & Alerts

Automated Item Counting

GS1 Decoding Standard

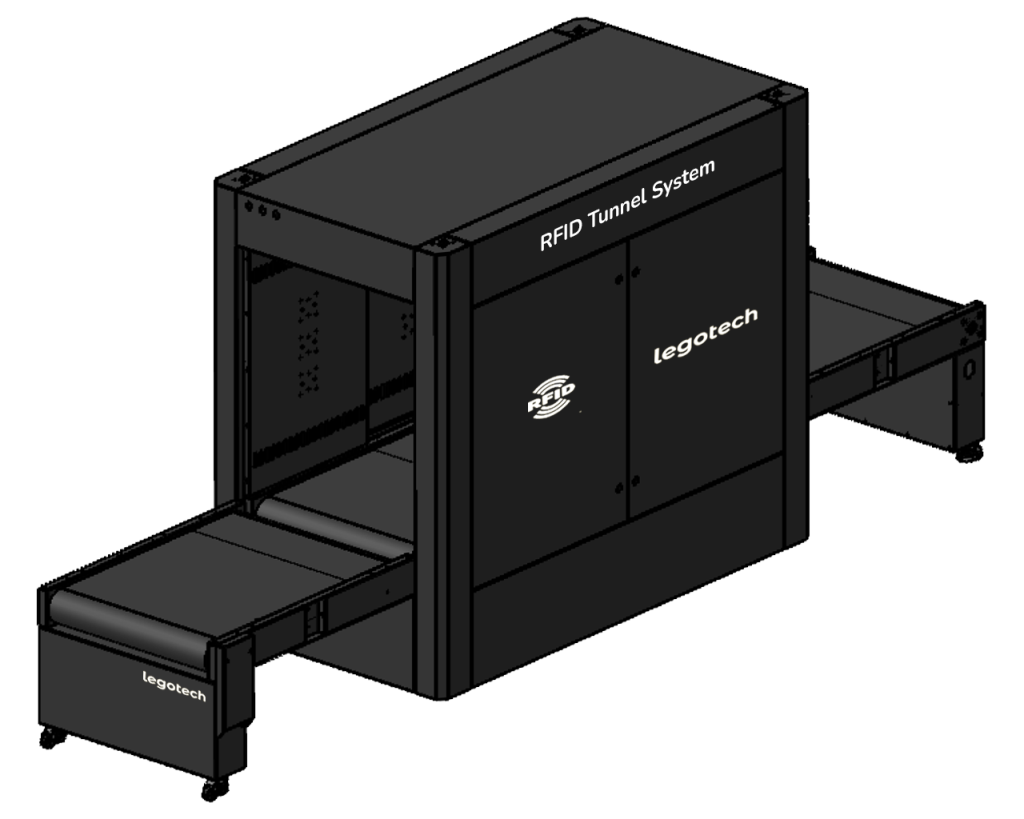

RFID Tunnel System

Conveyor Belt: Transports cartons or items through the RFID reading zone.

Reading Chamber:

4–6 UHF RFID antennas

1 high-performance RFID reader

Object detection sensors for item entry and exit.

Software: Captures and displays RFID read data in real time.

Signal Light & Buzzer: Indicate reading status (Pass/Fail).

RFID Printer: Prints and encodes RFID labels before application to goods.

RFID Tags/Labels: Attached to items or cartons for identification.

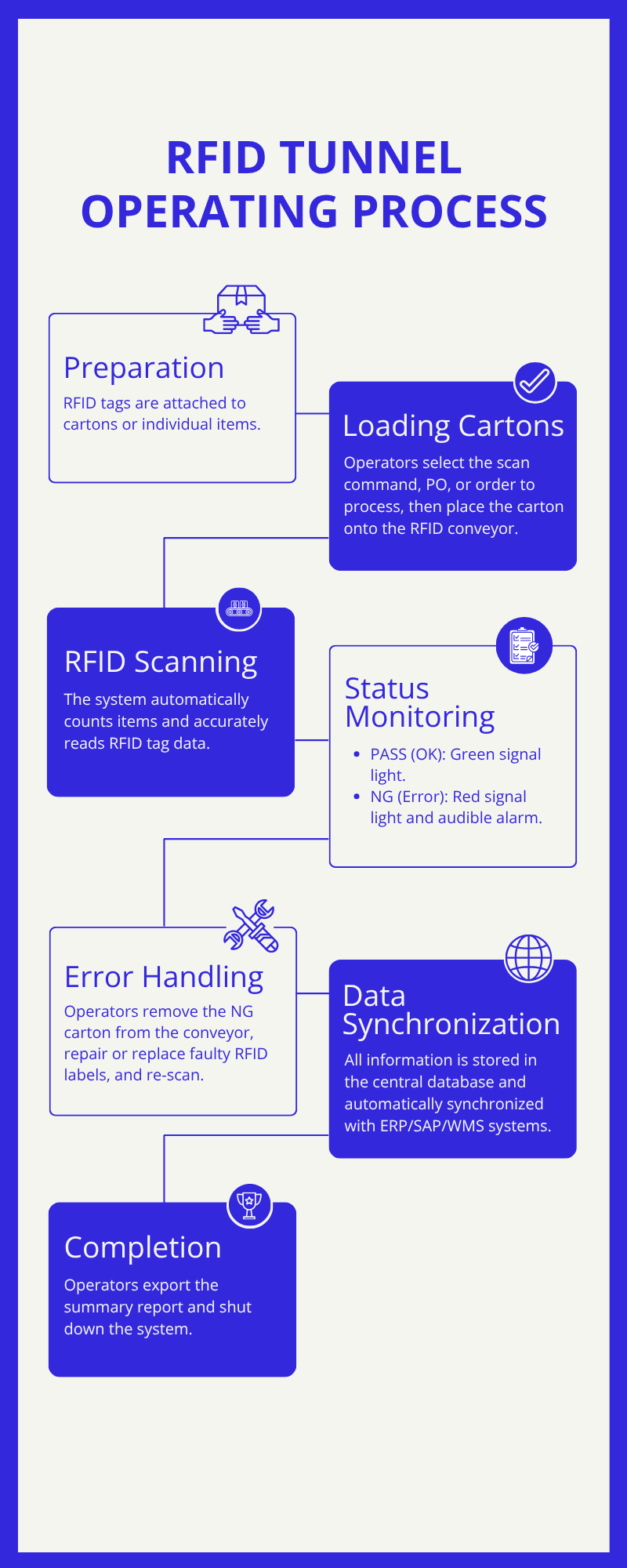

RFID Tunnel Operating Process

Preparation

RFID tags are attached to cartons or individual items. Each tag contains key data such as order number, product code, size, and color.Loading Cartons onto the Conveyor

Operators select the scan command, PO, or order to process, then place cartons on the RFID conveyor according to the following rules:Only one carton per scan.

Maintain 30–50 cm spacing between cartons.

Do not stack cartons.

Avoid metal objects or liquids near the RFID antennas.

Ensure consistent tag placement on all cartons.

Automatic RFID Scanning

The conveyor moves cartons through the RFID reading zone.

Antennas emit signals and capture RFID tag data.

The RFID reader transmits collected data to the management software.

Monitoring on Software Interface

PASS (OK): The number of tags read matches the expected count; the signal light turns green.

NG (Error): The system detects missing, duplicate, or unreadable EPC codes; the signal light turns red and the alarm activates.

Error Handling

Operators remove the NG carton from the conveyor.

In software, select Re-scan to identify faulty or missing tags.

Repair or replace defective RFID labels.

Re-scan the carton.

Data Recording and Synchronization

Once scanning is successful, all data is saved to the central database and automatically synchronized with ERP/SAP/WMS systems.- Process Completion

Operators export the summary report, shut down the system, clean the conveyor, and inspect antennas and sensors for maintenance.

RFID Tunnel Specifications

Weight: 230 kg ± 15 kg

Power Supply: 220V / 380V

Maximum Conveyor Load: 80 kg

Operating Temperature: 10°C – 45°C

Frame Material: Metal (Steel / Aluminum)

Conveyor Speed: 0.05 – 0.5 m/s

RFID Tunnel Dimensions: 1500 mm (L) × 960 mm (W) × 1650 mm (H)

Maximum Carton Size: 1200 mm (L) × 650 mm (W) × 750 mm (H)

- Incoming goods

- Outgoing goods

- Inventory

- Dynamic recording

- Retail

- Logistics and transport

Get in Touch

Have any questions? Reach out to us from our contact form and we will get back to you shortly.

Address

Phone

Contact Form

We can help you?

Find the RFID product or solution that meets your business needs.

Ask us to help you find the right decision.